See Details

See Details

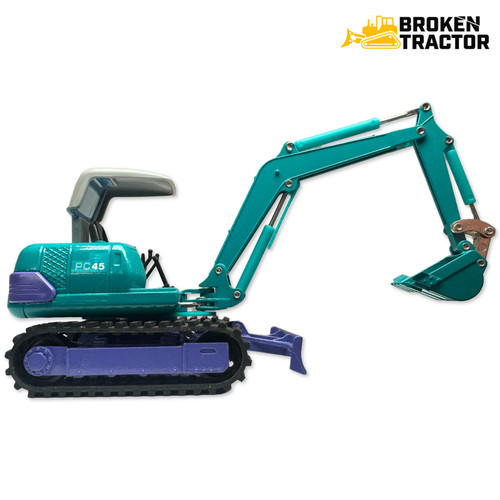

Komatsu PC45R Mini Excavator Specs and Parts

Komatsu

- SKU:

- Komatsu PC45R Mini Excavator Specs and Parts

- FitsModel:

- PC45R

- ListDescription:

- Komatsu PC45R Mini Excavator Specs and Parts

- exclude_in_klevu_search:

- 1

FEATURED PRODUCTS

Shipping & Return Policy

Do you need your part quickly? You're in luck! We have warehouses all over the country to ensure a quick and easy delivery time. Most of our parts ship from our warehouses the same day you place your order. And many times, orders are delivered in Two to Three days.

Our in house parts are manufactured following strict quality standards in our warehouse in Ohio. Parts such as hydraulic cylinders, pins, bushings, sheet metal, track adjusters, booms and dipper sticks are all ready to ship same day that they are purchased! With less time to wait for your shipment, you will be able to get back to work as quickly as possible.

Did you accidentally purchase the incorrect part? We offer returns and exchanges here at Broken Tractor. To proceed with a return, please call us toll free, and we will provide you with return authorization and a step by step return process for your convenience. We are more than happy to help you exchange your part for the correct one! Give us a call at 1-800-909-7060 and we would be pleased to help you.